Choosing a 3D Printer for the OLSK¶

The aim of the Open Lab 3D printer is to develop a DIY 3D Printer design that is robust and reliable. It should be possible for anyone to build it, with the posssibility of modifying it according to their budget, requirements and available resources.

Requirements¶

- The Open lab 3D Printer must be a reliable machine with quality components that can be built from scratch with having to source as few components as possible.

- The printer can be built locally without having to purchase an expensive Kit or fully assembled 3D Printer.

- The printer should make it possible for users to choose their own components for key elements depending on local availability of components and budget.

3D Printer Design Goals¶

- Enclosed and Stiff construction

- Reliable and repeatable print quality

- As much as possible can be built or sourced locally

- Configurable based on local resources

- No reliance on any manufacturer or proprietary hardware

Technical Specifications¶

- Build Volume :- 200x200x200 to 400x400x400 (Configurable?)

- Built in Enclosure

- Automatic bed levelling feature with inductive sensor

- Heated Build Platform (> 60 deg C - 110 deg C)

- Good Quality hot end (E3D V6 or clone)

- Use a direct-drive extruder (to print flexible filaments) / Bowden Extruder

- PLA, PETG, ABS and other std. materials

- Detect if filament finishes mid build or gets stuck

- Detect power loss and resume build

- Removable build plate (flex to remove part)

- HEPA Filter with Fan to remove fumes (for ABS printing)

- Emergency Stop Button

- 32 bit control capability

- Linear guides for fast accelerations

- Wifi Connectivity

- IP Cam to see build in real time

Further Requirements (For Workshops)¶

- Printable assembly and build instruction required.

- SD card, USB drive compatibility and display required.

- Aluminium profile ends needs to be closed with protection pads.

- All holes in profiles, enclosure plates or build plate needs to be drilled and deburred in advance

- Linear bearings needed to lubricated beforehand (or avoided by buying quality bearing like Misumi)

- Threaded inserts (Einpressmutter) needs to be inserted into printed parts before workshop and check possibility to replace inserts with nuts

- Firmware should already be uploaded to controller board with the right settings.

- All cables must be extended to have the right length with insertable JST ends (Workshop will have no soldering activity)

- No sharp corners

- AC wiring completely enclosed.

Design Categories¶

- Design 1 High End: (Similar or cheaper than Ultimaker < 2500€ )

- High end 3D printer with profesional grade print quality and speed

- Durable and high end components

-

Latest features Possibly look at the Voron V1.8 for this.

-

Design 2 - Mid Consumer (similar in price to Prusa i3 < 800€ )

-

Higher end 3D printer with most key advanced features that could be in the price range of the prusa i3

-

Design 3 - Affordable (Similar in price to Ender 3 < 200€ )

- 3D printer that is affordable in the range of the cheapest commercial good quality printer like the popular Creality Ender 3

- This could include similar design considerations in terms of components and mechanics

- Fully DIY so it can be built by anyone and almost anywhere in the world

- Should have all the very basics to allow someone to 3D print good parts

Current 3D Printer Design Log¶

Frame¶

For the outer frame of the design, we start with the Hypercube Evoution design by thingyverse user Scott3D which has a boxed construction that has been tried and tested for rigidity and stiffness. The boxed frame is also easier to enclose which is necessary for printing ABS that requires a controlled temperature environment for good layer adhesion. The enclosed frame is also more importantly kids (and pets) friendly. The frame squareness after building can be verified by measuring the opposite diagonals. If they are the same you know have a square structure.

Mechanics¶

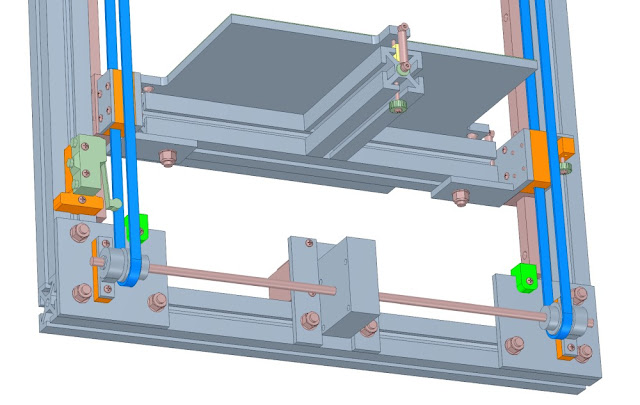

The design uses the CoreXY mechanism whereby the motors for the X and Y axis are fixed to the frame, which makes the X carriage that carries only the print head lighter than a conventional Cartesian design which has to carry the X axis motor. This should allow higher accelerations and printing speed.

CAD 3D Model¶

Scott3D the original creator of the Hypercube Evolution design has uploaded a parametrized and configurable CAD file in Autodesk Inventor. This needs some modifications since the parameters don’t work correctly in the original file. This is a good starting point but later designs will be carried out in Fusion 360 or Freecad. For now a build volume of 300cm3 will be used to build the first iteration.

Part of the design criteria is to fit the power supply and electronics under the base. This means the 3D printer is extended on the bottom by 100 mm but it has a clean look with increased safety by keeping electronics out of reach of (kids). Moreover, transport is easier and the printer can be easily placed on a desk. The printer size is increased on the top by 100mm to accomodate the moving cables of the print head during printing. The final frame size can be adjusted after the first prototype build, considering how space can be optimized within the printer.

Linear Bearings on Smooth rods Comparison¶

According to this Discussion on difference between various linear bearings 1. Bronze bushing - Smooth bearings but could suffer from slip-stick effect if not properly aligned. They also need to be regularly lubricated. 2. Linear ball bearings LMXUU (with X for shaft diameter) - Less smoother than bronze bushings but also louder. They are more forgiving of misalignment. They are also less susceptible to wear. 3. Igus bearings (special polymer bushing) - similar to bronze bushings and are also susceptible to slip-stick effect.

Linear ball bearings were chosen in two variants the LM8UU amd LM10UU - LM8UU for the X axis from Misumi, LM10UU for the Y-axis from Misumi and conventional LM8UU bearings for the Z-axis.

X-carriage Design¶

The current X carriage design has a vertically stacked linear rods design with 4 LM8UU bearings on the rods. The spacing between the X carriage rods is 45 mm. On some tests there seems to be some sticking of the bearings. Some users have debated the use of 4 or 3 bearings on the X-carriages. Normally 3 points are sufficient to fix somthing on a plane, and the fourth is over stabilizing. From various posts as well as the reliable Prusa I3 design, the 3 linear bearings seem to be the more tested design. The X-carriage now has just 3 bearings instead of 4.

Discussion on the use of 3 or 4 bearings

Lubricating linear bearings¶

Linear bearings come packed with just a corrosion inhibiting oil from and not really packed with grease. Therefore the bearings need to be soacked in isopropyl alcohol to wash out all the OEM oil (soak in alcohol for an hour with intermittent swishing). Then let the bearings dry on sheets of paper towel. Apply a grease like Superlube using a 3D printed lubricator fitting from here and end cap from here. Print the grease application fitting from PETG filament with 0.2 resolution and layer width of 0.42. Apply the grease by inserting the printed grease cap into the linear bearings and aligning the slots with the balls and pressing the tube till the grease comes out of the top of the bearing. Then the bearings needs to be slided on the smooth rods multiple times so the rolling of the balls can allow equal grease distributions. Excess grease can be wiped off. Reapply the grease on the bearings and repeat the sliding of the bearings on the smooth rods procedure. This ensures all the balls are sufficiently lubricated. Source

Belts and Pulleys¶

Most commonly used belts in 3D printers are the GT2 belts which are toothed rubber belts which can have different reinforcing fibes such as steel, fibreglass or just rubber. The GT2 belt is usually 6mm in width and has a pitch of 2 mm. Accordingly the pulleys used are called GT2 pulleys. The size of the pulleys are specified by the inner bore diameter, the number of teeth and if the pulley is a smooth idler, toothed idler or toothed pulley(i.e. no free bearing inside) to connect to a motor for instance.

6mm wide rubber GT2 belts are used in the design. According to experience for users of CoreXY printers, here belts with steel reinforcement are to be avoided since these are not elastic enough and so can cause wobbling or misalignment of the idlers. Rather fibre reinforced rubber belts are to be used.

- Toothed GT2 Pulley

- Smooth Idler GT2 Pulley

- Toothed Idler GT2 Pulley

Electronics¶

- Control Board - MKS Sbase V1.3 - most affordable 32 bit board and long term use has shown no problems.

- Mechanical Endstops for X nd Y

- Heat Bed heating options

- 220V mains heating - fast heating but requires care with wiring

- 24V DC heating

- heat bed types

- Silicone Bed Heater

- MK23 Aluminium Heated bed - PCB Heat bed

- Kapton heater

- Z-bed levelling sensor choices:

- Induction Sensor

- BL touch

- IR sensor

- Piezo Sensor

Most common Z-bed autolevelling sensors are reviewed and tested in the following video, whereby the most simple and precise seem to be the PINDA 8mm inductive sensor from Prusa and the LJ12A3-4-Z/BX inductive sensor.

Inductive sensors are affordable and precise enough for our application and so we will use a 12mm LJ12A3-4-z/BX inductive sensor. This has a 4mm metal detection distance (for ferrous metal like iron) but for non ferrous metals like aluminium this distance can be halved. So the inductive sensor will have to be placed about 2 mm offset from the nozzle head.

Cooling fans used¶

- 120mm Fan for Hepa Filter (Exhaust)

- 50mm Duct fan for part cooling

- 30mm Fan for Hotend cooling

Configuring the MKS Sbase V1.3¶

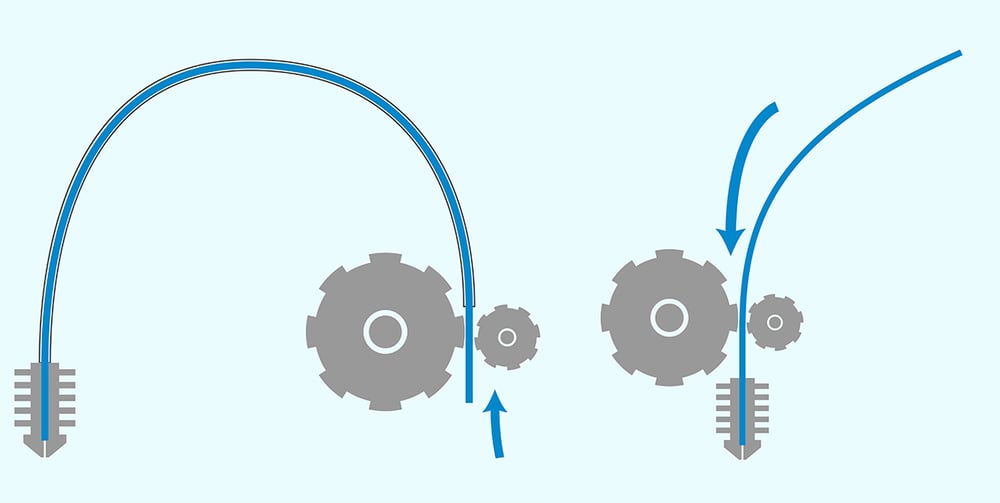

Direct Drive vs Bowden Drive¶

Most filament 3D printers use either direct or bowden extrusion. Both set-ups use an extruder to push filament through a heated nozzle, either directly or through a bowden tube. Though similar, these extruder formats have major differences. See links below for more information. Both options are possible.

Direct Drive Extruder Selection Guide

Z-axis design for lifting Build Platform¶

The current design uses 2 lead screws attached to Nema17 motors ot lift the build platform along with 4 linear rods to constrain movement on XY plane. Other possible design variations for the Z-axis are discussed below. Using two motors to lift the bed can cause problems with synchronization. One option would be to use one motor along with pulleys and a belt to run multiple screws. This solves the problem of syncing.

Discussion 1, Discussion 2 on RepRap Wiki about the optimal number of lead screws, motors and guide rails combination to lift the build platform of a 330x330 cast aluminium build plate. Some of the possible designs are:

- Original HEVO design by Scott3D of 2 lead screws + 4 12mm linear shafts(rods), run by 2 Nema Motors

- 4 lead screws along with 4 linear shafts on four corners of build platform driven by 1 Nema17 motor and a belt and pulleys.

- 3 lead screws + 2 linear shafts run by pulleys/belt and single Nema17 motor.

- 2 lead screws + 4 linear shafts driven by 1 Nema17 motor with belt and pulleys

- 20 teeth pulley on motor and 40 teeth pulleys on lead screw

-

Thingiverse Design from Gavitka and his CAD model on Onshape

-

Single stepper motor with 2 belts on either side to lift bed [design]/https://drmrehorst.blogspot.com/2017/07/ultra-megamax-dominator-z-axis-design_65.html)

Calculating travel on Z - axis¶

Using 1.8 degree motor with T8x8 four start lead screws gives 8mm travel per rotation with 200 steps (1.8 degree motor) and 400 steps (0.9 degree motor). This is 0.04 mm and 0.02 mm respectively.

Choosing Stepper Motors for the X,Y and Z axes¶

While choosing the stepper motor for moving the various axes in the 3D printer, several basic calculations can be done to determine the minimum required torque for running the printhead without skipping steps with a specific velocity and acceleration.

Look at the following links for more details on the calculation:

How microstepping reduces motor torque

According to above article microsepping by 1/16 reduces motor torque by 90%, so if the nema 17 motor had a torque of 40Ncm, with 1/16 microstepping only about 4Ncm remains.

Calculating minimum motor torque for X and Y axes¶

- In a coreXY setup, only the X gantry has to be moved since the Y axes are supported on the frame.

- The X gantry consists of the following parts:

- 2xLM10LUU bearing =

- 2x8mmx370mm long steel rods =

- Extruder Head

- E3D V6 Hotend

- Sherpa Mini Extruder

- Printed parts

- part cooling fan

- Hotend cooling fan

Calculating motor torque for Z axis (Bed platform)¶

All Metal Hotend vs PTFE Lined Hotend¶

All metal:

- Works well for high (+250ºC) temperatures filaments like nylon or PC.

- No need to replace the PTFE liner (pretty obvious).

- Retraction performs worse.

- Plastic can get stuck to the inner walls. This can lead to clogging, more likely when changing from ABS to PLA (higher temp plastic to lower temp plastic).

PTFE liner hotend:

- Limited working temperature. Above 250 PTFE will start to degrade.

- PTFE tube needs to be replaced more or less often, depending on the use of the printer.

- Retraction performs better.

- Plastic is less likely to get stuck in inner wall (PTFE is very nonstick).

- When using PTFE liner, the plastic is melted very close to the nozzle. Unlike other techniques, in FFF/FDM 3D printing this is more desirable. E.g. to avoid ‘heat creep’, for a better flow control and more accurate output dimension. Source

Comparison of three popular Nozzles¶

- Slice Engineering’s Mosquito - 165 Euros

- This is a high end well engineered hotend with a copper heat sink and copper alloy heater block.

- Triangle Lab’s Dragon - 60 Euros

- The dragon design takes the heater block design from the E3D V6 and the heat sink design from the mosquito and at a price of 60 Euros is the better option of the three. The copper heatsink allows the possibility of a less bulky cooling fan option. This however will not be used since it seems to infringe on the pending patent by slice engineering mosquito hotend.

- E3D V6 (Original or Triangle Lab clone) is the most popular hotend in the 3d printing market and has been shown to be reliable and made with good precision and quality. The original costs 70 Euros while a good clone from the Trianglelabs costs about 15 Euros. The heat sink here is however aluminium which has worse conductivity than copper and so needs much more cooling in an enclosed heated chamber for instance. Also changing the nozzle required dismounting the entire hotend.

Comparison Video from User Nero3DP who has had thousands of hours printing experience with the respective nozzles.

All three print relatively similarly good for the average user if they are correctly calibrated. However, they each have some advantages and disadvantages as listed above. Best Budget Option is the E3D V6 from trianglelabs which prints perfecttly well but maintainence and nozzle changes are difficult.

Heated Bed Choice¶

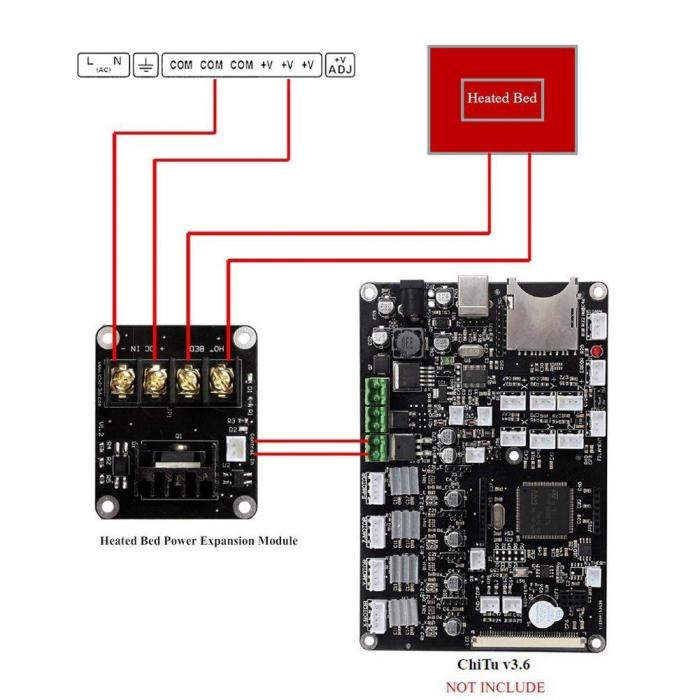

A heated bed helps with layer adhesion in part and prevents warping of the part due to rapid cooling. Moreover, most plastics other than PLA cannot be printed without a heated bed. Even PLA prints much better with a 60degC heated bed. PETG for instance with 70degC and ABS with 110 degC. Firstly one must figure out how much power is required for the specific build plate size and material. The following Online Calculator can be used to calculate time needed to heat an aluminium or glass build plate with heatbed platform of specific size and power. The heated bed is the most power hungry part in a 3D printer build. Therefore the choice of the heated bed directly influences the choice of power supply unit (in terms of power rating).

A solid state relay (SSR) or external MOSFET is often used to switch the bed heater power by connecting its control terminals to the controller board bed heater terminals. An SSR helps by taking the current load away from the controller board and preventing the controller board mosfet from frying, incase of a current surge or high current draw. Make sure that you get the wires to the + and - control terminals of the SSR the right way round.

Caution: when using a high-powered bed heater, in the event that temperature control fails and the bed heater is turned on at full power for an extended period of time, you should either make sure that the bed heater and bed will not exceed a safe temperature, or else install a thermal cutout to disconnect the bed heater or its power supply before excessive temperatures are reached. This is important since if the SSR fails, it fails in the ON-state and this can lead to the heated bed running without interruption. Here the thermal fuse will break power to the heatbed once the temperature of the heatbed exceeds the thermal fuse specific temperature.

There are two ways of heating the heatbed 1. via DC power i.e. through the power supply unit or 2. via mains power supply. Below both ways are described along with precautions required.

Mains voltage AC bed heater¶

Use a zero-crossing DC-AC SSR such as Crydom D2425, Kudom KSI240D25-L or Fotek SSR-25DA (note: many Fotek SSRs on sale are fakes, using triacs rated at lower current than the marked rating of the SSR). For 230V bed heaters, SSR-10DA may be sufficient. If your bed heater draws more than about 1/4 of its rated current then the SSR may need a heatsink.

Take appropriate safety precautions when using a mains voltage bed heater. In particular:

-

Connect metal parts of the printer to mains ground. This includes the printer frame, the bed plate if it is conductive (e.g. aluminium), and any other metal parts that the bed heater or SSR wiring might come into contact with if wires break.

-

Ensure that it is not possible for the user to touch the SSR terminals or any other exposed mains wiring, or for you to touch the mains wiring when you are working on the printer with power applied. If your SSR is not supplied with a clear plastic safety cover, buy one (for the Crydom SSR listed above, the part number is KS101).

-

If the bed is moving, use highly-flexible wire or cable with a sufficient voltage rating to connect the moving bed heater to the stationary wiring. Cable intended for use in multimeter tests leads is one possibility.

-

If the bed is moving, you must use strain relief at both ends of that cable, to reduce the risk of the cable fracturing with repeated movement.

-

If the bed is moving, use a cable chain or similar to make sure that the cable can’t get chafed or trapped.

-

Provide a fuse for the bed heater circuit or the whole printer appropriate to the current draw and the current rating of the mains lead. One option is to use a panel mount IEC mains inlet connector with a switch, neon indicator and fuse built in. See http://www.thingiverse.com/thing:965396 for an example setup on a delta printer. It is highly recommended that you power the printer via a Ground Fault Current Interruptor (GFCI) - more commonly called a RCD (Residual Current Device) in the UK - to protect against electric shock in the event of a fault.

-

Fruitful discussion on Duet website regarding 24v silicon heater vs AC mains silicon heater

The following tutorial video from youtuber Teaching Tech, explains the procedure of installing an AC mains silicon bed heater along with configuring it in Marlin.

Low voltage (12V or 24V) DC bed heater¶

Use a low voltage drop DC/DC SSR such as the Auber Instruments MGR-1DD80D100 or Crydom DC100D40. The SSR may need a heatsink, depending on the current. Do not be tempted to use a cheap DC-DC SSR such as the SSR-40DD, which is basically useless for this application because of its high voltage drop.

If your heater will reach dangerously high temperatures if it is left on at full power, you should always use a TCO (Thermal cutout) to guard against electronics or firmware failure. The alternative is to choose the heater power carefully so that it is powerful enough to reach the temperatures you want quickly, but not so powerful as to reach a dangerously high temperature when left fully on for a long time.

- use 12AWG wire from PSU > Mosfet and 12AWG Silicon high temp wire from mosfet to heater for DC heater

Choosing Power Supply¶

Connected Heated bed with Mosfet and power supply

The next most important rating for your 3D printer power supply is output current. As previously stated, this will be the limiting factor for your heated bed and the total number of hot ends you are operating.

The easiest way to calculate how many amps you need is to look at the wattage of the supply, and the rating of your heated bed. Generally, your control board, one hot end, five motors, and a few other electronics (sensors and fans) can be said to use about 100 watts of power. Add in what your heated bed is rated for, and you’ll have a minimum required wattage for your power supply.

To get the amperage, simply divide by the output voltage, e.g. 360W / 12V = 30A.

Here are some examples:

- The standard minimum for 3D printers is usually 240 watts (12 volts @ 20 amps). That would be enough for a printer with a single hot end and a heated bed around 180 x 180 mm.

- With a 200 x 200 mm bed or a second hot end, you’d be better off with 300 watts (12V @ 25A). With both a second hot end and a 200 x 200 mm heated bed, or single extruder with up to a 300 x 300 mm heated bed, 360 watts are standard (12V @ 30A).

- With anything larger than that, a power supply rated upwards of 400W would be recommended. With a 24V PSU, the rules change slightly, as you don’t need quite as much current. Still, we would recommend sticking to the above standard for the best possible operation.

There are two main kinds of power supplies:

ATX PSUs are generally meant for PCs, and while they are manufactured to a higher standard than LED supplies, they require modification to be used with 3D printers. They are also usually more expensive, especially at higher ratings, but incorporate many more safety features, not least of which is closed AC wiring and (usually) a power switch.

LED PSUs are what you will usually find on a kit like the Anet A8 — that clunky silver box with the really dangerous wiring terminal. These supplies are generally pretty reliable, and they’re cheap and easy to wire. However, there’s no real standard for these supplies to be manufactured to. That means quality will vary a lot based on the seller and manufacturer. The single biggest issue with these supplies is the open AC screw terminals, which are a safety hazard if left uncovered.

The best way to check an LED PSU is with a voltmeter or multimeter. First, wire up your supply to the appropriate power cord, making sure that it is not plugged in while you are handling the wires. When done, plug in your supply, and check the voltage across the output terminals. Be very careful not to touch or short the input AC power terminals.

When checked with a voltmeter, the output should be nearly the same as the indicated output voltage. You may need to fiddle with the small potentiometer next to the screw terminals, as this will change the output regulation slightly. Having the voltage slightly higher will help with an underpowered heated bed, but be careful not to overpower your other components.

Once you know your supply works, wiring it into your printer should be relatively easy. This is especially true with screw terminals and the plug-and-play style setup adopted by most manufacturers. Again, be very sure that you never do any wiring while the supply or the printer is plugged in. Also, be very careful to not touch or short the AC terminals of your PSU while running tests.

If you accidentally touch both AC terminals, or if they short to each other, it’s very easy to electrocute yourself or burn things down. Therefore, to finish up we would recommend you avoid either of these instances by investing the time and filament printing a covering for any exposed wires and terminals. It’s also a good idea to add a switch and a fuse in the process. Example of covering the PSU terminals below.

https://all3dp.com/2/3d-printer-power-supply-how-to-choose-the-right-one/

https://all3dp.com/2/3d-printer-power-supply-how-to-choose-the-right-one/

3D printer Wiring¶

One of the most important things about your 3D Printer is the Wiring. If the wire gauge is too small you won’t get enough current to your parts and can even lead to busted cables. Too large of a gauge and you might have a problem fitting those crimped terminals into the connectors. So, the first thing to look for in a wire type is a stranded wire. The reason being your printer will create thousands of cycled movements and if your wire is a solid it will be susceptible to break over the duration of repeated abuse. The stranded wire allows for the cable to flex and move without breaking over time.

A few useful tips: Depending on your level of expertise it may be useful to practice crimping and soldering before wiring everything up. Bad crimps are a major source of problems later on an sometimes hard to identify! Safety Mains cables should be properly dimensioned. Use at least 20 AWG for mains connections, even better would be 18 AWG. Buy a quality SSR, do not source one from china or your house will catch on fire (see Official Sourcing Sheet)! Add a 115-125°C thermofuse to your bed heater as an additional safety measure. Dont run your bed above 105°C, this greatly reduces the lifespan of the adhesive holding it onto the build plate Connect ground to your bed! Connect a ground to your frame!

Connectors The recommended MicroFit 3.0 connectors are specced up to 5A and should be used for all connections to the stepper motors, hotend and limit switches The dupont connectors are used for connections to the RAMPS board Adding molex connectors to all stepper motors is useful. You can disconnect motors while moving the gantry manually to avoid damage to the RAMPS board. Use a 3pin MLX connector (see the official sourcing guide) to allow your bed to be removable without disconnecting from the SSR directly. The thermistor can use a 2pin microfit connector.

Cables The specced silicone wire has been chosen because: It is very high strand count, which means it has higher fatigue life Silicone insulation withstands heat and is more flexible which is good in high movement applications It is less prone to snagging on other wires or the walls inside the cable chain Check you cable loom before installing the tape chains. You need at least: 8x 24AWG wires in the z chain (2 steppers) 4x 24AWG wires in the y chain (endstops) 7x 24AWG (probe, fans, thermistor) 2x 20AWG in the x chain (heater) - do not downsize these, they are oversized for safety reasons SOURCE from VoronDEV website

Instructions on setting up the power connector.

Points to be noted

The hot end and thermister wires are not polarity dependent so the + and - can be plugged in anyway.

3D Printer Wiring Connectors¶

Dupont Connectors

These connectors work great for RAMPS and Rumba type controller boards with open Pin Headers.

JST Connectors

The JST connectors are what are used on the 32 bi boards such as the MKS, AZteeg etc.

Wiring exmaple of the MKS Sbase V1.3 Board -

- Great instructable on wiring up the various electronics:

Inserting threaded inserts in Printed Parts

Inserts are put on one end of a 3d printed part whereby the bolt can screw in providing the same functionality as a nut. However since inserts are pressed with heat into the 3d printed part, the hot insert melts the plastic around it and thus forming a very strong bond. Thus inserts have a higher pull out strength than a normal nut that is press fit. Inserts nuts can require precise holes that aren’t too small that the nut won’t go in and not too big that nut has no plastic to grip on to. When the pull out force is in the direction of which there is no material, the nut could be pulled out when tightening the bolt. This is where a heated insert needs to be used due to its pull out resistance.

Configuring Marlin for MKS Sbase v1.3¶

The compiling of the Marlin configuration can be done using visual studio. The Platform.io extension in visual studio needs to be installed before that. Platform.io can be used to make changes to the configuration file and upload the compliled firmware/configuraton file to the 3D printer. The latest release of Marlin can be downloaded from Marlin’s Github repository. Extract the contents of the zip folder and place the entire folder in the VS workspace.

Open the ‘platformio.ini’ file in the ‘marlin-2.0.x’ folder and change the ‘default_envs’ variable of the default atmel to LPC1768. This is the CPU on the MKS Sbase V1.3, and needs to be defined here. Save and exit the platformio.ini file.

Before You Begin to get your core Configuration.h settings right you’ll need to know the following things about your printer:

- Printer style, such as Cartesian, Delta, CoreXY, or SCARA

- Driver board, such as RAMPS, RUMBA, Teensy, etc.

- Number of extruders

- Steps-per-mm for XYZ axes and extruders (can be tuned later)

- These can be calculated easily using Prusa’s Online Calculater

- Endstop positions

- Thermistors and/or thermocouples

- Probes and probing settings

- LCD controller brand and model

- Add-ons and custom components More Information on how to change the configuration according to your setup can be found on Marlin’s Configuration page. Source

Next Open the file Configuration.h with the file path - Marlin-2.0.x > Marlin > Configuration.h.

Here the first thing to define is the motherboard used i.e. here after #define MOTHERBOARD enter BOARD_MKS_SBASE as seen in the code snippet below.

- More advanced settings can be found in Configuration_adv.h

Defining Motherboard type¶

// Choose the name from boards.h that matches your setup

#ifndef MOTHERBOARD

#define MOTHERBOARD BOARD_MKS_SBASE

#endif

Setting Stepper Steps¶

Considering we are using a GT2 belt of (i.e. distance between two teeth) pitch 2mm and our pulleys have 20 teeth. Therefore distance covered with one full revolution of the 20T pulley will be 40mm. Given that we have 1.8deg stepper motors, i.e. each step of the stepper. This means one full revolution of 360 degrees will be covered in 360deg/(1.8deg) = 200 steps for one full revolution. Considering we have default 1/16 microstepping as default on the MKS Sbase board i.e. each step will be further broken down into 16 steps. This means we will have 16 * 200 = 3200 steps for each revolution.

Calculating Steps/mm = Total Steps / Total distance per Rev

= 3200 / 40

= 80 Steps/mm

The value of 80 can be input then for the X and Y steps/mm in Marlin.

For the Z axis we have a lead screw which has a pitch of 8mm and a lead of 8mm. This means each revolution moves the lead screw nut 8 mm. Assuming again 3200 steps per revolution - this gives Steps/mm to be 3200/8 = 400 Steps/mm for Z axis motor.

For the extruder motor, first tryout is with an MK8 extruder fixed to frame (bowden setup), for which this website shows the extruder steps calculation along with assembly steps for the MK8 extruder. This gives the value to be 93 steps/mm which can be further fine tunner by running some tests according to this video

A sherpa mini direct drive extruder which is a fully open source design for a lightweight direct drive extruder, has been ordered which once assembled will be calibrated accordingly and setup on machine. But for now, the MK8 bowden drive will be tested first.

Configuring Extruder Steps¶

This is a useful video tutorial on how to calibrate or set the extruder steps in Marlin for a bowden drive (MK8 extruder here).

Configuring NPN NO 12mm inductive probe¶

An inductive probe can be attached to the Z-min Endstop pins in the controller board to use autobed levelling. The 3 inductive probe wires will be attached to the Z-min endstop port which has three pins namely V(voltage), S (Signal) and G (Ground). If the inductive probe is a 5V probe, it can be connected directly to the Z-min Endstop. However, if the NPN NO or NC inductive probe is rated 6-36V or 10-30V (most common), it cannot be connected directly to the Z-min Endstop since the 5V from the Z-min Endstop V pin will not be sufficient to power the probe. The probe will then have to be powered with full 24V from the PSU. Consequently, the output signal from the sensor to board will have the same voltage as the input signal and as our board is rated 24V, it powers the sensor with 24v and therefore the output signal will also have 24v. This could fry the Signal pins on the Z-minstop connector if not reduced since they are rated for a maximum of 5V. This can be fixed in two ways:

- Using a resistor divider setup to reduce the voltage across the G and S pins to be less than 5V.

- Using a transistor

- Using an Optocoupler

The voltage divider setup does not work since the pullup resistors within the MKS Sbase V1.3 board need to be deactivated in the firmware to use the voltage divider. However, this cannot be done through the firmware. The transistor method however works. The following page explains the method to attach the transistor to the NPN NO probe. The user also had no problems making the 18mm inductive probe work with the voltage divider setup but not the 12mm inductive probe.

This is an interesting video describing the setting up of an NPN NO inductive probe and levelling the Z-probe manually using Repetier Host.

Discussion about the use of optocouplers or a transistor to power the NPN probe.

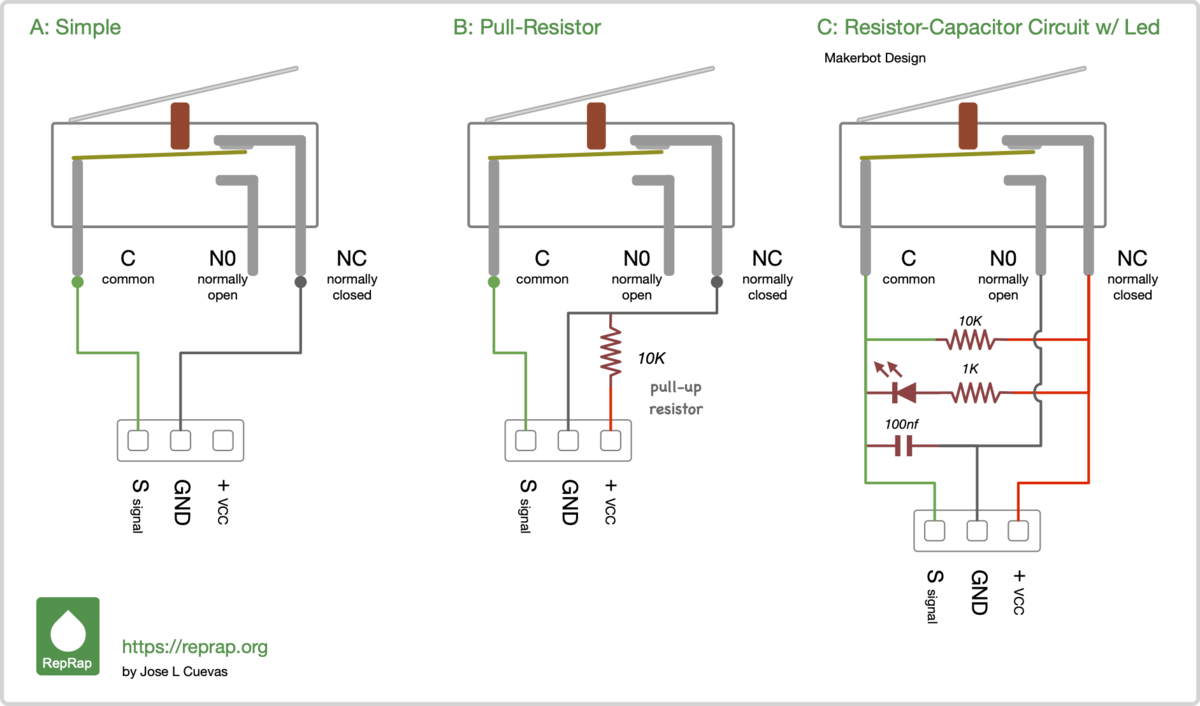

Wiring a mechanical EndStop¶

The optical endstops that were purchased turned out to be defect i.e. the endstop showed open before any trigger but once triggered, they stay triggered. Only one out of 6 endstops worked normally, the rest all turned out to be defective. So instead a mechanical endstop was wired according to the Simple setup shown to act as the Y axis minimum endstop as shown . Whereby the C pin on endstop was connected to signal pin on Y-min Endstop and NC pin was connected to Ground pin on Y-min endstop on controller board. This creates a normally closed Y endstop which is important so that incase the endstop fails, the endstop will be triggered

. Whereby the C pin on endstop was connected to signal pin on Y-min Endstop and NC pin was connected to Ground pin on Y-min endstop on controller board. This creates a normally closed Y endstop which is important so that incase the endstop fails, the endstop will be triggered

Tutorial video on connecting a mechanical endstop

Connecting LEDs¶

Good video explanining different methods to connect LEDs

Setting motor current in Marlin¶

Motor current can be defined in config_adv.h file whereby the digipot option needs to be enabled. Due to a software bug marlin does not compile. The following fix needs to be made as seen here

Initial Bed Levelling, First Layer Thickness and Z-Offset¶

Levelling the bed or setting the gap between the nozzle and the bed is done to let the machine know where exactly the bed is. Levelling the bed is crucial to getting a even first layer because it lets the nozzle extrude even across the entire bed. We need both a level build surface and correct nozzle gap to get an even first layer. Then we have the perfect foundation for the rest of our 3D print job. This is usually done with a thin piece of paper being inserted between the nozzle and bed, untill the nozzle just grabs the paper. We are essentially looking to have zero gap between nozzle tip and bed so that the machine can know where exactly Z=0 is i.e. on the bed surface. Understanding the concept of bed levelling and first layer thickness is nicely explained in the following article(https://www.3dmakerengineering.com/blogs/3d-printing/bed-leveling-first-layer-thickness-and-z-offset).

Even though the milled aluminium build plate is flat, it sits on 3D printed brackets and so the bed will not sit on a completely flat plane and will be slightly tilted. Therefore, the build platform needs to be levelled by adjusting the levelling screws. This process is well explained in the following article.

The bed levelling screws were turned 5 full turns to tighten the aluminium build plate mounted on the 4 springs. The bed was heated to 70degC (to let it expand) and after a few ,minutes, the axes were homed and the nozzle was brought manually to the front left corner of the build platform. A thin piece of paper (mine was 0.08mm measured with a Vernier Caliper - the thinner the better) was inserted between nozzle and bed, and the bed levelling screws tightened (tightrning the bed levelling screws compresses the springs and the bed is pulled down towards the bed brackets and distance between nozzle & bed increases) or loosened (distance between nozzle and bed decreases), untill the nozzle just grabbed the piece of paper. The process is repeated on the four corners of the bed i.e. near the four bed levelling screws. Finally it is done in the center of the bed.

Note: For printing PETG use a normal (thin) paper and for printing PLA use a business card (thicker than normal paper). For PETG the first layer needs to be squished slightly more in order to grip the build surface.

Sending print commands¶

There are 3 ways to print a part from the printer namely: 1) via the internal onboard SD card - Here the print job (gcode) can be copied on to the oboard SD card. The on-board SD card is inserted back into the controller board, and the print job (gcode) can be found under the option ‘Print from media’. However this is a little cumbersome, since the micro SD card has to be constantly inerted and removed from the controller board. 2) via an external SD card connected to an LCD display - Not all LCD display SD card slots work with the MKS Sbase V1.3. Currently the LCD display is a full discount RepRep Smart Controller LCD. This works with a hack that involves turning the EXP connectors on the back of the LCD controller 180 degrees. However, the SD card on the controller does not work without a tricky wire hack. This is mainly a problem with marlin. The REpRAP display SD card works fine with smoothieware. The SD card on the TFT 32 or TFT 28 displays from MKS work with marlin and so next step will be to get one of these. 3) directly via the computer using a host software - Repetier host can be used to connect to the printer controller board via the Laptop. A print job can then be uploaded to the SD card by saving the gcode file as XYZ.GCO. This allows then printing from the onboard SD card. The transfer is however slow.

Setting up MKS TFT32 Display¶

To configure the TFT32 display and install firmware, go to Github repo from Makerbase and download the zip folder for TFT28-32 display.

- Extract the contents

- Open Config folder and copy out the “mks_config_EN.txt” file and rename it to remove the “_EN” since that causes problems > file renamed to “mks_config.txt”

- Go to Firmware > TFT28 32 firmware > Retro > mkstft28.bin

Calibration & Fine Tuning Methods¶

Printer Calibration cross from thingiverse.

Thingiverse Post of finetuning the CoreXY setup

Instructable on good practices for building 3d printer

A nice way of presenting bill of materials

Guide on troubleshooting and Calibrating

Next Improvements¶

The surface finish of 3d printed parts is generally good other than some ringing or ghosting that is visible. According to this blogpost(Insert link), this can be attributed to the slack from belts or wobbling idler pulleys. Users have countered these issues in several ways:

1) Better quality GT2 belts (gates original) 2) Wider belts - for example 9/10mm belts. Current design has 6mm belts. 3) 5mm bore idler pulleys instead of current 3mm bore pulleys. 4) 5mm smooth shaft for idler pulleys instead of 3mm bolt as shaft in current design 5) Put XY motors outside the Printer ENclosure - Check HEVORT’s XY Gantry style 6) Use of Trinamics Silenstick stepper drivers since the current DRV8825 stepper drivers inbuilt in the MKS Sbase are too loud. A good overview and comparison of the various TMC drivers can be seen here

Optional Features (Future Work)¶

- Detect and pause print when filament runs out

- 3D printed design with mechanical roller switch

- Pause print when enclosure door opens

- Segmented Heatbed

- Wifi connectivity with Rasberry Pi (Octoprint)